Smart Solutions For Your Business

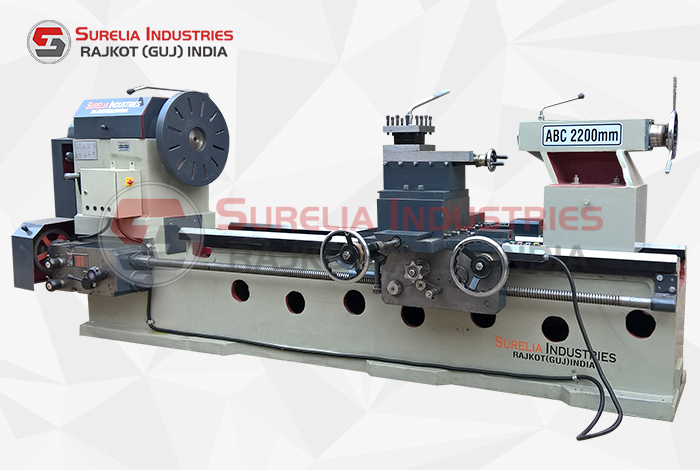

Surelia Industries is an experienced Plano Bed Lathe machine manufacturer offering a wide range of Extra Heavy Duty Plano Bed Lathe machines. We have highly skilled & experienced engineers who fabricate these machines using tested components & the latest technology as per the required Industrial Standards.

We supply these machines in various specifications with V Belt Driven and All Geared Driven option as per various requirements of our customers.

All Details Of Our Product

- Low maintenance

- Smooth operation

- Longer functional life

- High Tensile Strength Casting

- Latest Design Head Stock

- Induction Hardened & Precisely Ground Bed ways

- Alloy Steel Material done with induction Hardened Process & Highly Precised Ground Spindle

- Width of Bed: 324 mm

- Spindle Bore: 52 mm

- Height of Center: 250 mm

- Admit Bet Center: 555 mm

- Size Length of Bed: 1670 mm

- HP Required – 3 HP

- Length of Bed – 10 feet

- Spindle Bore – 4.1/8 inches

- of Spindle Speed – 6

- Swing in Gap – 52 inches

- Swing In Gap: 725 mm

- Swing Over Bed: 480 Mm

- Approximate Weight: 1200 Kg

- Swing Over Cross Slide: 285 mm

- Leading Screw Dia – 1¾ inches

- Height of Center – 16 inches

- Admit between Centre – 72 inches

- Width of Bed – 18 inches

- Swing over Bed – 32 inches

- Phase – 3

- Automation Grade – Automatic

- Main Motor – 1440 rpm

- Max Swing Over Bed – 500-750 mm

- Lathe Machine Type – Horizontal Lathe

| Standard Technical Specifications | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| MODEL | Bed Length | Admit Between | Width of Bed | Swing Dia. Over Bed | Swing Dia. Over Carriage | Swing Dia. Over Cross Slide | Swing Dia. In GAP Bad | Weight | Floor Space | |

| Center Height 508mm (20″) | Approx KGs. | L x W | ||||||||

| 24205 | 7ft. (2130mm) | 600 | 609mm (24″) | Dia. 965mm (38″) | Dia. 800mm (32″) | Dia. 700mm (28″) | Dia. 1370mm (54″) | 3500 | 2500 x 1600 | |

| 924205 | 9ft. (2740mm) | 1200 | 3950 | 3100 x 1600 | ||||||

| 1024205 | 10ft. (3050mm) | 1500 | 4350 | 3400 x 1600 | ||||||

| 1224205 | 12ft. (2660mm) | 2100 | 4750 | 4000 x 1600 | ||||||

| 1424205 | 14ft. (4270mm) | 2700 | 5150 | 4600 x 1600 | ||||||

| 1624205 | 16ft. (4880mm) | 3300 | 5650 | 5200 x 1600 | ||||||

| 1824205 | 18ft. (5480mm) | 3900 | 6050 | 5800 x 1600 | ||||||

| 2024205 | 20ft. (6100mm) | 4500 | 6550 | 7000 x 1600 | ||||||

| 2424205 | 24ft. (7315mm) | 5100 | 7450 | 7600 x 1600 | ||||||

| 2624205 | 26ft. (7920mm) | 6700 | 7850 | 8200 x 1600 | ||||||

| 2824205 | 28ft. (8530mm) | 7300 | 8350 | 8800 x 1600 | ||||||

| 3024205 | 30ft. (9150mm) | 7900 | 8750 | 9400 x 1600 | ||||||

| General Specifications | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Bed Typed | 2V & 2 Flat typed | Induction Hardened & Precisely Grounded Bedways | |||||||

| Spindle Speeds (In V-Belts Driven) | 8 Speeds | 20 to 300 rpm | |||||||

| Spindle Speeds (In All-Geared Driven) (OPTIONAL) | 16 Speeds | 12 / 380 rpm | |||||||

| Spindle Nose (In Belt Driven) | 6 TPI | MT-7 | A2-8 -OR- A2-11 (OPTIONAL) | ||||||

| Spindle Bore | Std. Bore 130mm / 155mm Available | ||||||||

| Tailstock Ram Dia. | 76.1 mm | ||||||||

| Tailstock Taper Size | MT – 5 | ||||||||

| Nos. of Feeds for LONGITUDINAL (With Change Gears) INCH & MM | Infinitely Variable | ||||||||

| Nos. of Feeds for TRANSVERSE (With Change Gears) INCH & MM | |||||||||

| Nos. of Feeds for LONGITUDINAL (With Norton Gear Box) INCH & MM | 0.065 to 1.98 mm/rev. | ||||||||

| Nos. of Feeds for TRANSVERSE (With Norton Gear Box) INCH & MM | 0.016 to 0.48 mm/rev. | ||||||||

| Transverse Movement in MM | 500 / 600 | ||||||||

| Nos. of Threads & Range (Norton Gear Box) | 28 in INCH | 20 in MM | |||||||

| 1.5 to 22 TPI | 0.75 to 16 | ||||||||

| Lead Screw Dia. / TPI | 50 / 2TPI | ||||||||

| Elc. Motor Requires (2-Speed) | 7.5 HP / 10 HP | 960 / 1400rpm | 3 Phase | 50Hz | |||||

| Standard Accessories | Recommanded Accessories (OPTIONAL) | |||

| Induction Hardened & Precisely Ground 2V & 2Flat Type Bed Ways | True Chuck | |||

| Dog Chuck | 1no. | Steady Rest | ||

| Chuck Back Plate | 1no. | Follow Rest | ||

| 7.5HP. 3Phase, 960 / 1440 RPM Elc. Motor (2- Speed) | 1no. | Face Plate | ||

| Motor Pulley | 1no. | All-Geared Headstock | ||

| V-Belt | 1no. | Norton Gear Box Having INCH & MM Threads | ||

| R/F Switch + wiring Complete | 1Set. | Electro Coolant Pump with Tank & Stand Fittings | ||

| Spindle Nose Sleeve | 1no. | Taper Turning Attachment | ||

| Dead Centers | 2nos. | Anti Vibration Leveling Ped Sets. | ||

| Tool Post Key | 1no. | Revolving Center | ||

| Service Spanner Set. | 1Set. | Machine Lamp Stand | ||

| Alen Keys Set | 1Set. | Quick Change Tool Post | ||

| Change Gear Set INCH / MM | 1Set. | Tool Post Grinnding Attachment | ||

| Oil Cane | 1no. | Key-Way Cutting Attachment with Elc. Motor | ||

| Milling Vice | ||||

| Splash Guard | ||||

| PLANO Type Extra Heavy Duty Bed Available in all above model on request | 155mm (6″) Spindle Bore | |||

| COMPLETE CNC CONTROLED RETRO FITTING HAVING LATHE MACHINE | ||||