Smart Solutions For Your Business

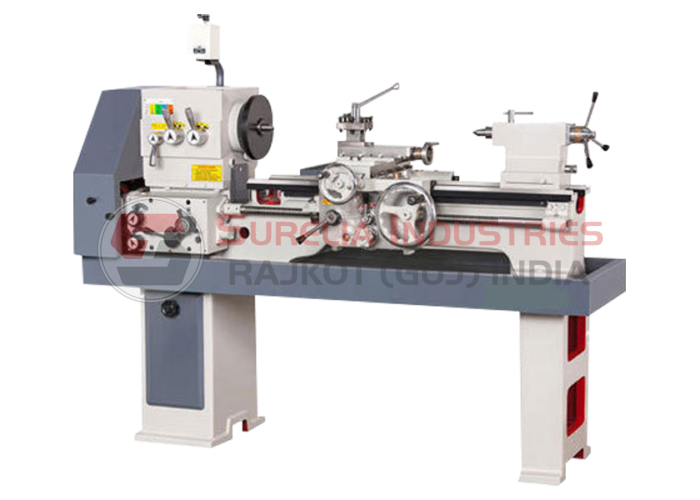

Surelia Industries are the widely appreciated Light Duty Lathe Machine manufacturers offering a wide range & customized designs as per the specific requirements of the customers. Light Duty Lathe Machine is made using excellent quality raw materials and is economical & durable for use.

This machine is specifically used for precision production work, tool room purpose, and college purpose. We conduct stringent quality checks on these machines before supplying to ensure the high quality & efficiency of these machines.

Short Details Of Product

- Height of Center: 190mm (7.5”)

- Width of Bed: 240mm (9.5”)

- Swing Dia. Over Bed: 300mm (12”)

- Swing Dia. Over Cross Slide: 170mm (6.5”)

- Spindle Bore: 40mm (1.55”)

- Admit Between Centers: 380mm to 1115mm

All Details Of Our Product

- Surface 5″

- Leading Screw 1″

- Change Gear 16 D.P

- Compound 3 ½””

- Main Gear Straight

- Pan Gear 14 D.P

- One Leg Box Type One Leg C-type

- Plain V-Belt

- Long lasting

- Sturdy construction

- Smooth performance

- Precisely engineered

- Low noise

- Energy Efficiency

- Cost effective

- Makes industrial work easier, quicker, defect-free & reliable

- Advanced Design

- Bed made of 25 Grade Cast Iron of 180 BHN hardened, inspected with Microlevel, Hardness Tester & Straight edge.

- It has a square shaped Tail Stock with hardened & ground tail stock Spindle made of alloy steel having external & internal grinding.

- Head Stock is available in all geared and is totally enclosed oil bath system & gear made from EN-8 (Liquid night riding).

- Apron is fully enclosed oil bath system with lever type arrangement for automatic feeds.

- Boring of Head Stock is performed on WMW boring machine fitted with induction hardened & ground spindle made of alloy steel.

- Color options are Oasis Green / Blue & White (Two tone)

| Standard Technical Specifications | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Specifications | Admit Between Center | Width of Bed | Swing Over Bed | Swing Over Carriage | Swing Over Cross Slide | Swing in Gap Bed | Weight | Floor Space | |

| MODEL | Bed Length | Center Height 190mm (7.5″) | KG | L x W | |||||

| SILD – 3 | 3.5ft (1065mm) | 380mm(15″) | 240mm(9.5″) | Dia. 300mm(12″) | Dia. 230mm(9″) | Dia. 170mm(6.5″) | Dia.450mm(17″) | 400 | 1370 x 1000 |

| SILD – 4 | 4.5ft. (1370mm) | 725mm(28.5″) | 480 | 1600 x 1000 | |||||

| SILD – 5 | 5.3ft. (1600mm) | 915mm(36″) | 550 | 1980 x 1000 | |||||

| SILD – 6 | 6ft. (1830mm) | 1115mm(44″) | 600 | 2100 x 1000 | |||||

| Bed Type | 2V & 2Flat Typed | INDUCTION Hardened & Precisely Grounded Bedways | ||

| Spindle Speeds (In V-Belt Driven) | 8 Speeds | 40 to 1000 | ||

| Spindle Speeds (In All-Geared Headstock) (OPTIONAL) | 16 Speeds | 45 to 2400 | ||

| Spindle Nose Type | Threaded 8TPI | MT-5 | A2-4 (OPTIONAL) | |

| Spindle Bore | 40mm (1.5″) | |||

| Width of Bed Gap In Front of Face Plate | 135mm (5.25″) | |||

| Cross Slide Travel | 180mm (7″) | |||

| Top Slide (Compound Slide) Travel | 110mm (4.25″) | |||

| Tool Sank Size | 20mm (0.75″) | |||

| Tailstock Ram Dia. | 38mm (1.5″) | |||

| Tailstock Quill Travel | 110mm (4.25″) | |||

| Tailstock Taper Size | MT-3 | |||

| Nos. of Feeds for LONGITUDINAL (With Change Gears) INCH & MM | Infinitely Variable | |||

| Nos. of Feeds for TRANSVERSE (With Change Gears) INCH & MM | ||||

| Nos. of Feeds for LONGITUDINAL (With Norton Gear Box) INCH & MM | 32 / 0.068 to 1.02 mm/rev. | |||

| Nos. of Feeds for TRANSVERSE (With Norton Gear Box) INCH & MM | 32 / 0.012 to 0.185 mm/rev. | |||

| Transverse Movement | 180mm (7″) | |||

| Nos. of Threads & Range (Norton Gear Box) | 32 in INCH | 15 in MM | ||

| 4 to 60 TPI | 0.5 to 12 | |||

| Lead Screw Dia. / TPI | (1″) 25.4mm / 4TPI | |||

| Elc. Power HP Requires | 1HP / 0.75 kw | 1440 rpm | 3 Phase | 50Hz |

| Standard Accessories | Recommanded Accessories (OPTIONAL) | |

| INDUCTION Hardened & Precisely Grounded 2V & 2Flat type Bed Ways | Dog Chuck | |

| True Chuck | 1no. | Steady Rest. |

| Chuck Back Plate | 1no. | Follow Rest |

| 1HP. 3Phase, 1440 RPM Elc. Motor | 1no. | Face Plate. |

| Motor Pulley | 1no. | All-Geared Headstock |

| V-Belt | 1no. | Norton Gear Box having INCH / MM Threads |

| R/F Switch + wiring Complete | 1Set. | Electro Coolant Pump with Tank and Stand Fittings |

| Spindle Nose Sleeve | 1no. | Taper Turning Attachment |

| Dead Centers | 2nos. | Anti-Vibration Leveling Pads Set. |

| Tool Post Key | 1no. | Revolving Center |

| Service Spanner Set. | 1Set. | Machine Lamp Stand |

| Alen Keys Set | 1Set. | Quick Change Tool Post. |

| Change Gear Set INCH / MM | 1Set. | Tool Post Grinding Attachment. |

| Key Cutting Attachment. | ||

| Milling Vice. | ||

| Splash Guard | ||

| COMPLETE CNC CONTROLLED RETRO FITTING HAVING LATHE MACHINE | ||