We Provide All Kind Of Lathe Machines

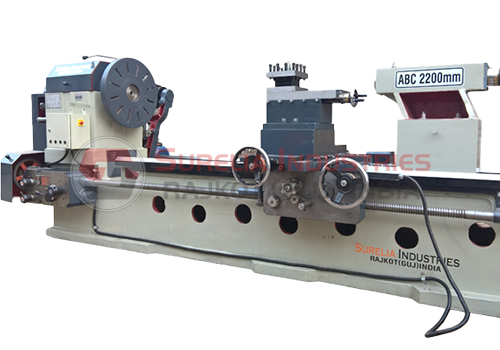

Surelia Industries is one of the foremost Heavy Duty Lathe machine manufacturers supplying machines to various parts of the world to work.

We supply these machines in various specifications with V Belt Driven and All Geared Driven option as per various requirements of our customers.

We work hard on bringing the latest technology in use & also offer customized All Geared Lathe Machines as per customer’s specific requests.

Welcome To Surelia Industries

- It is fast, reliable, consistent & works with precision.

- It doesn’t let the work material slip off from the machining platform.

- The V Belt feature ensures repitable accuracy in the machine.

Request a Free Call Back

We’ll inspire and assist you.

Team Of Professionals

Mr. Ketan Surelia

![]()

Best Custom Lathe Machines

We design these machines using powerful features with high capacities to turn large metal workpieces.

Surelia Industries has years of experience in the production of machines & tools.

We have years of experience in manufacturing various specifications of V Belt driven Lathe machines.

We are a leading Horizontal Lathe Machine manufacturer in Gujarat.

Doing the right thing at the right time

Planning

We are a small group of engineers and experts. We have combined experience of over 25 years. We can help you with our best products.

Management

Surelia Industries is one of the leading manufacturer, supplier, and retailer of a wide custom range of Heavy & Light Duty Lathe Machines.

Export Area

We are a leading exporter of HD Lath Machines, Belt Driven Lath Machines, and Plano Bed Lathe Machine based in India.